BASE and Arup Partner for Innovation

Base Bahay Foundation, Inc. (BASE) and Arup have launched a new collaboration aimed at advancing affordable, sustainable, and disaster-resilient housing solutions in the Philippines and beyond.

The partnership builds on a shared commitment to addressing the urgent housing challenges faced by vulnerable communities, particularly those exposed to climate-related disasters. By combining BASE’s expertise in bamboo-based construction systems with Arup’s global engineering knowledge, the collaboration seeks to strengthen technical innovation and promote scalable, resilient housing models.

A Shared Vision for Resilient Communities

BASE, a non-governmental organization established by the Hilti Foundation, has pioneered the development of bamboo construction technology in the Philippines. Its construction system uses bamboo for structural framing and has been demonstrated to be both environmentally sustainable and disaster-resilient.

Engr. Luis Felipe Lopez, BASE General Manager, highlighted: “This collaboration with Arup marks a significant milestone in Base Bahay’s commitment to advancing bamboo structures as a powerful solution for resilience and sustainability. By uniting our expertise in bamboo-based construction with Arup’s world-class engineering support, we are strengthening the foundations of innovative building systems that can protect communities, withstand disasters, and create a more sustainable future for the Philippines and beyond.”

Arup, an international engineering and design consultancy, has also worked extensively on similar construction systems across Latin America. Both organizations share a history of collaboration through the development of technical guidelines and codes that support safe and effective bamboo housing solutions.

Sebastian Kaminski, Associate from Arup, stated: “With construction contributing towards 40% of global carbon emissions and over 1.6 billion people worldwide living in inadequate homes, we need to develop appropriate, durable, and resilient housing that is also low carbon. Bio-based materials such as bamboo can play an important role in this materials’ transition. We believe that BASE’s work is key to scaling the use of disaster-resilient bamboo housing worldwide. We have always been impressed with how Base works closely with local communities, the number of houses that Base has built, and the very positive influence that BASE has had at a regulatory level.”

This renewed partnership reflects mutual trust and a collective ambition: to accelerate the adoption of sustainable building technologies not only in the Philippines but also in other countries where resilient housing is urgently needed.

Supporting Innovation Through the Material Accelerator Programme

The collaboration is being undertaken as part of Arup’s Material Accelerator Programme (MAP). Through this initiative, Arup provides pro-bono technical support to organizations selected through The Earthshot Prize network, helping innovators scale impactful climate and sustainability solutions.

Under this partnership, Arup will support BASE in further improving its construction system, exploring new innovations, and documenting advancements that can inform wider implementation in countries such as India, Fiji, Nepal, and other developing contexts.

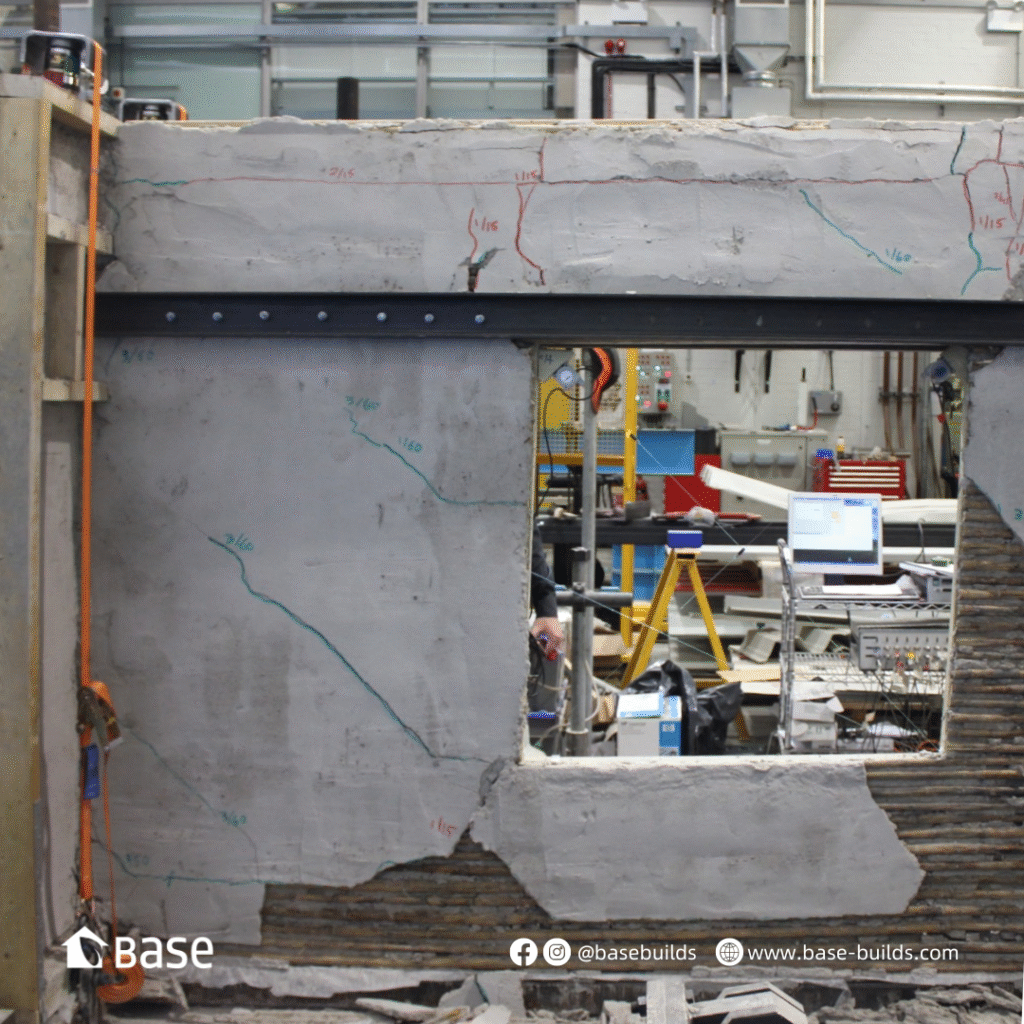

“Arup will leverage its materials, seismic engineering and international development domain experience to continue to support the improvement of the current composite bamboo shear technology in terms of affordability, resilience, durability and embodied carbon. We also plan to work with Base to help standardise and scape this technology worldwide, by engaging with governments, NGOs, UN agencies and regulatory committees,” Kaminski stated.

Building Toward a Sustainable Future

This collaboration represents a significant step forward in the effort to make housing not only affordable but also sustainable, safe, and resilient in the face of increasing climate risks.

By strengthening the technical foundations of bamboo-based construction and supporting innovation through global expertise, Base Bahay and Arup are contributing to a future where more communities can access dignified homes built with local, renewable materials.

“Bringing a new construction technology to the mainstream is challenging, and there are many hurdles. We believe that working closely in partnership with BASE can allow us both to draw on each of our strengths and tackle multiple barriers simultaneously,” Kaminski added.

Together, the partnership demonstrates how engineering, social impact, and sustainability can intersect to create solutions that are scalable, climate-responsive, and transformative.