In recent years, sustainable building practices have gained immense popularity as individuals and industries strive to reduce their environmental impact and create more eco-friendly structures. One remarkable material that has captured the attention of professional builders globally is bamboo. Bamboo has emerged as a viable alternative to traditional construction materials, offering a number of benefits that contribute to sustainable building practices.

When it comes to selecting bamboo varieties, several options show particularly favorable characteristics. Here are some of them:

Genus Guadua

Genus Guadua comprises approximately 20 or more different species, all of which are characterized by their remarkable size. These massive bamboo varieties grow in the tropic and subtropic regions such as Central and South America. Guadua species are known for their impressive growth potential, reaching towering heights.

Guadua Bamboo is one of the most ideal bamboo species to use in construction. Due to its straightness, it allows an easy application to structure and provides a good consistency in design as compared to curved bamboo. Along with that, due to its short internode length, this provides more support for the building by adding additional resistance. Currently, BASE is investigating different plantations in the Philippines for Guadua Bamboo for potential testing on its characteristic strengths.

Genus Dendrocalamus

Dendrocalamus is a genus of bamboo plants that is primarily found in the tropical and subtropical regions of India and Southeast Asia. It consists of numerous species that play an important function in the construction industry. One notable species within this genus is Dendrocalamus asper, commonly known as giant bamboo. This particular variety is widely utilized in heavy construction projects across Indonesia and the Philippines.

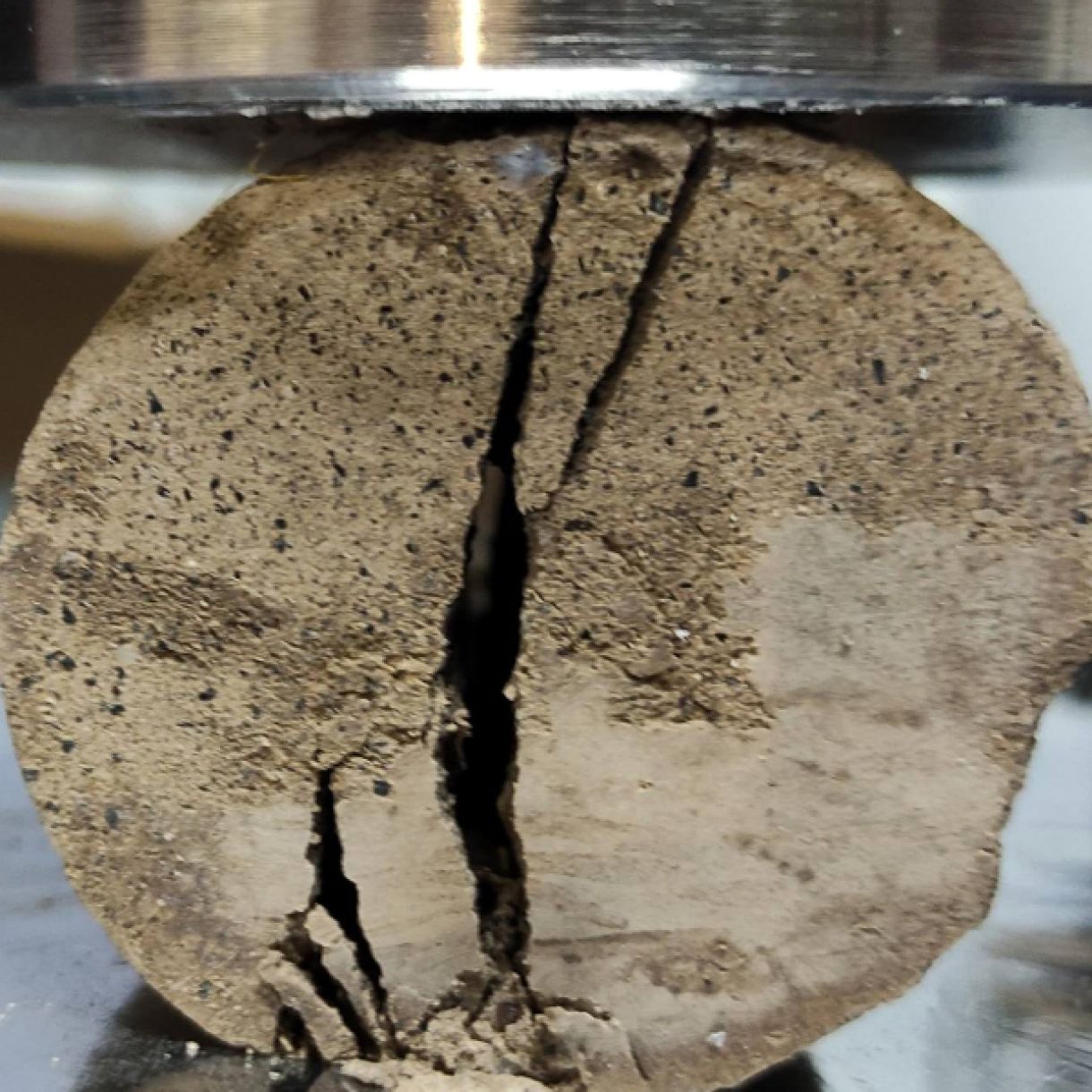

BASE is performing several mechanical property tests on Dendrocalamus Asper to obtain its characteristic values. The average strength of this species of bamboo in compression ranges from 40 to 60 Megapascals with some samples reaching around 20 tons capacity.

Genus Phyllostachys

Phyllostachys bamboos encompass a wide range of benefits, serving various purposes. One particular species of Phyllostachys is Phyllostachys edulis, commonly known as Moso bamboo, holds significant importance due to its remarkable culm size and versatile range of uses.

Genus Bambusa

Genus Bambusa are known for their aesthetic appeal and widespread cultivation in gardens and landscapes. Bambusa bamboo exhibit a wide range of sizes, with certain species capable of reaching impressive heights and featuring culms with diameters measuring several centimeters. However, it’s important to note that the size of Bambusa bamboo can vary depending on the specific species and the prevailing growing conditions.

In the Philippines, a well-known bamboo species is Bambusa blumeana or Kawayang Tinik. This bamboo species is recognized for its structural grade properties when mature and is frequently available within the country. BASE is now almost complete with all the mechanical properties to be conducted with this species. Through partnership with different universities in the Philippines, BASE hopes to publish into a journal the findings of the characteristic values of this species for future design with structural grade bamboo such as Bambusa Blumeana.

As the world increasingly focuses on sustainability and environmental consciousness, the utilization of bamboo in construction is becoming more prominent. Bamboo possesses remarkable strength, exhibits rapid growth, and offers versatility, making it an ideal choice for those who are seeking sustainable alternatives. However, it is crucial to note that not all bamboo is applicable for construction. They must undergo proper treatment and tests before being used as a building material. Collaboration with BASE can contribute to the development of sustainable practices and ensure the proper use of bamboo, promoting a greener approach to construction.

Base Bahay Foundation, Inc (BASE) is the pioneer of Cement-Bamboo Framework in the Philippines. BASE builds affordable and disaster-resilient structures using an innovative bamboo-based technology. Through continuous research in the Base Innovation Center (BIC), BASE is optimizing the technology and looking for new applications outside its standard model. The BIC is also equipped with the latest technology for testing different bamboo species and alternative building systems. Additionally, BASE offers training courses under its Bamboo Academy program to extend its alternative building technologies to different communities and provide further knowledge on bamboo construction. Build with BASE and engage in sustainable construction.