Authors

Martin Aldrin De La Cruz, De La Salle University

Luis Felipe López, Base Bahay Foundation Inc.

Richard De Jesus, De La Salle University

Lessandro Estelito O. Garciano, De La Salle University

Abstract

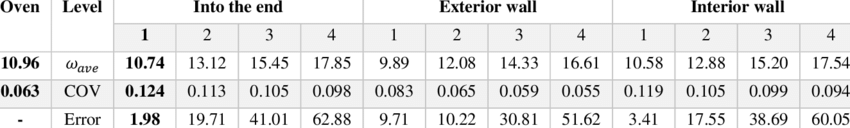

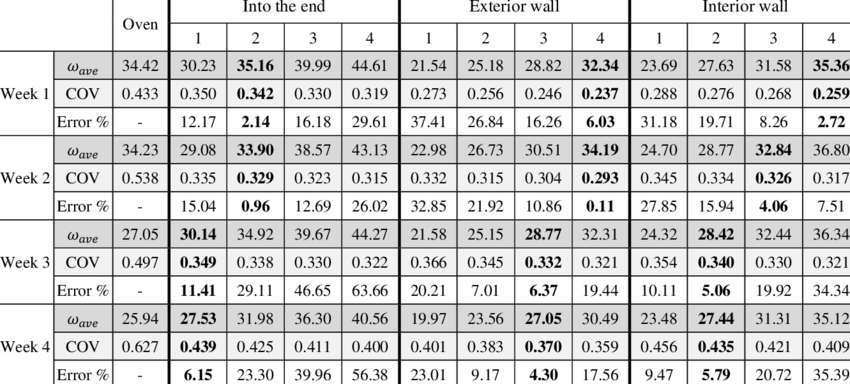

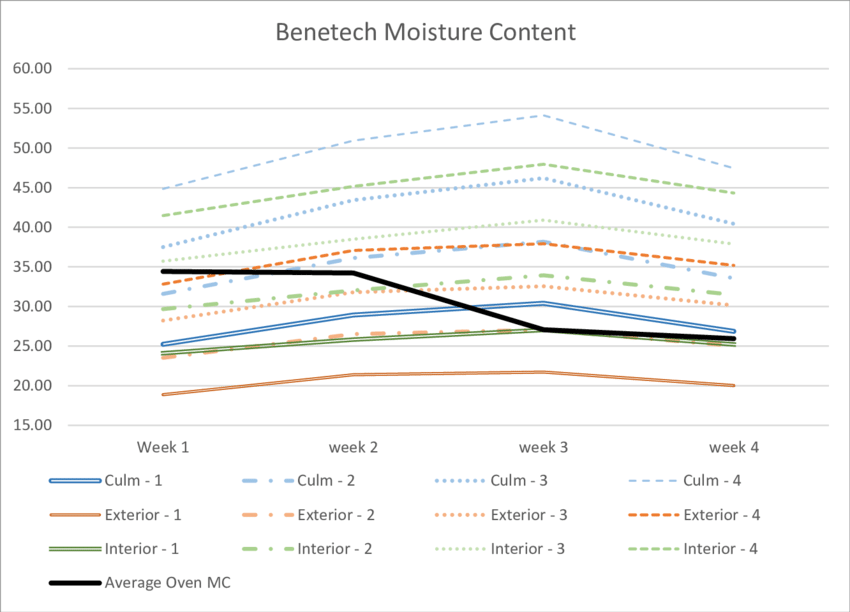

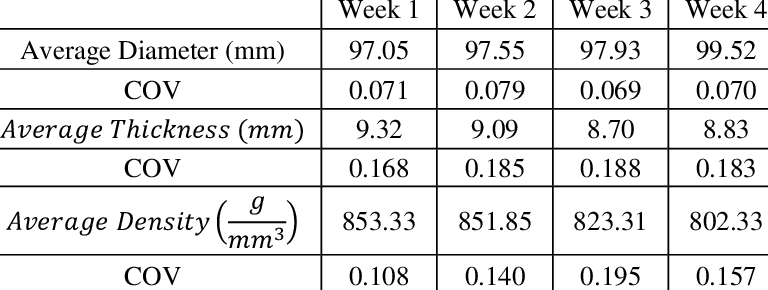

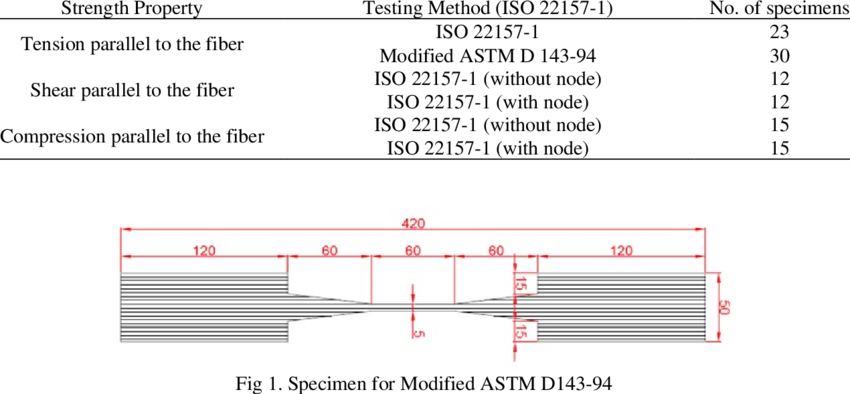

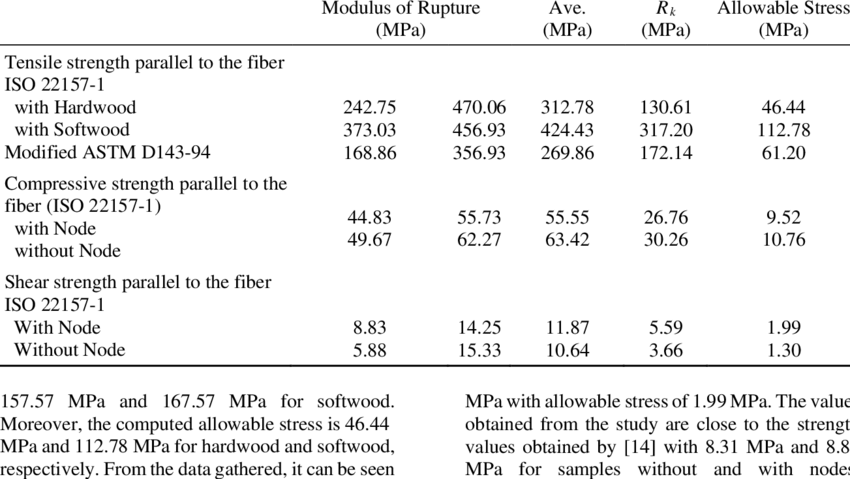

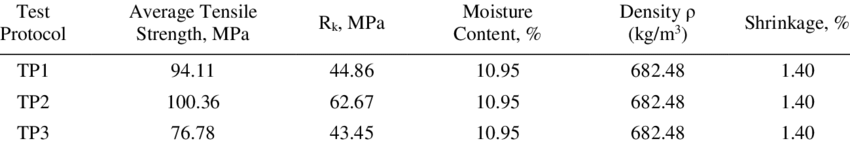

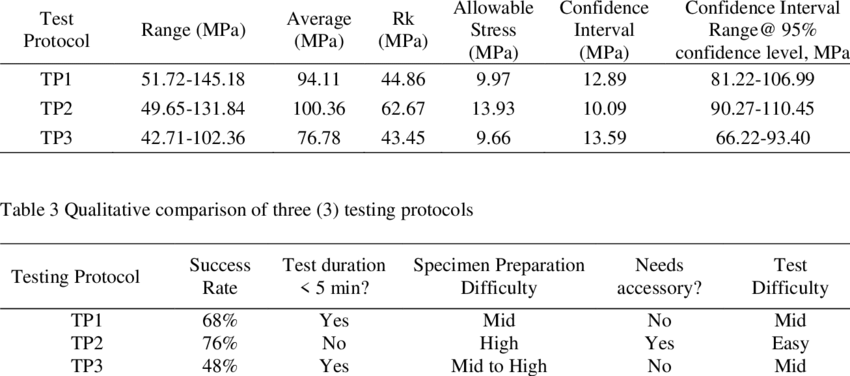

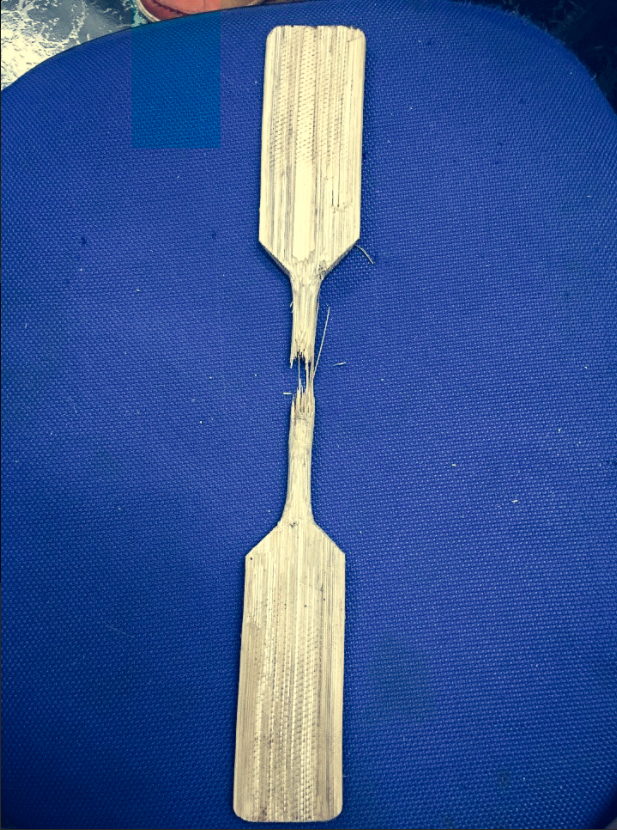

To determine tension parallel to fiber properties of Bamboo, one can employ ISO 22157. However, several studies highlighted some challenges in using the method such as premature failure of testing due to force at clamping and slipping failure at the grips. Hence, this study aimed to look for a solution to address these challenges. This study investigated, both qualitatively and quantitatively, three testing protocols in determining bamboo’s tensile strength parallel to fiber-(1) ISO 22157, (2) a modification of ASTM D143, and (3) Pittsburgh Method. The success rate, test duration, load rate and transmission, specimen preparation, equipment fabrication, and execution of the three protocols were compared. The physical properties of bamboos, such as moisture content, density, and shrinkage, were also measured in the study. The results of the study showed that the modified ASTM D143 test is the most viable method to use in testing the tensile strength parallel to fiber of bamboos. Modified ASTM D143 produced the highest tensile strength with value equal to 100.36 MPa, compared to specimens tested under ISO 22157 with tensile strength only reaching 94.11 MPa, while Pittsburgh Test produced the lowest tensile strength of 76.78 MPa. Modified ASTM D143 also yielded the lowest confidence interval which implied good consistency. Modified ASTM D143 is the recommended test protocol based on the results of this study as it gained the highest success rate during testing, lowest testing duration, and the easiest to execute.

Figures