Bamboo’s Role in Driving the Circular Economy

Amidst the global environmental challenges we face, prioritizing sustainability has become imperative. One notable solution gaining traction is the transition towards a circular economy. The circular economy represents a fundamental shift in the way we produce and consume goods, moving away from the traditional linear “take-make-dispose” approach. It promotes a model where resources are utilized for as long as possible, with their value maximized through practices such as recycling, reusing, repairing, and remanufacturing.

At its core, circular economy is based on three principles:

- Eliminate waste and pollution

- Circulate products and materials (at their highest value)

- Regenerate nature

Bamboo, with its remarkable properties and characteristics, presents significant opportunities to support the principles of a circular economy. Recognizing this potential, BASE, through extensive research, training, and value chain development, developed the Cement-Bamboo Frame Technology (CBFT).

In this blog, we will delve into the role of bamboo in driving the circular economy, highlighting CBTF’s contributions to a more sustainable and efficient economic system.

Sustainable Material

As we have known, Cement-Bamboo Frame Technology utilizes bamboo, a renewable and fast-growing resource, as a primary construction material. Bamboo has a minimal environmental impact compared to traditional construction materials like wood or steel. By incorporating bamboo into the construction value chain, CBFT promotes the use of sustainable and regenerative materials, reducing the reliance on non-renewable resources and supporting the circular economy’s principle of resource efficiency.

Waste Reduction

CBFT minimizes waste generation throughout the construction process. Bamboo culms are utilized efficiently, leaving very little waste behind. Additionally, any byproducts or residues from bamboo processing can be repurposed or recycled, contributing to a closed-loop system. By reducing waste and maximizing resource utilization, CBFT aligns with the circular economy principle of eliminating waste.

Extended Lifespan

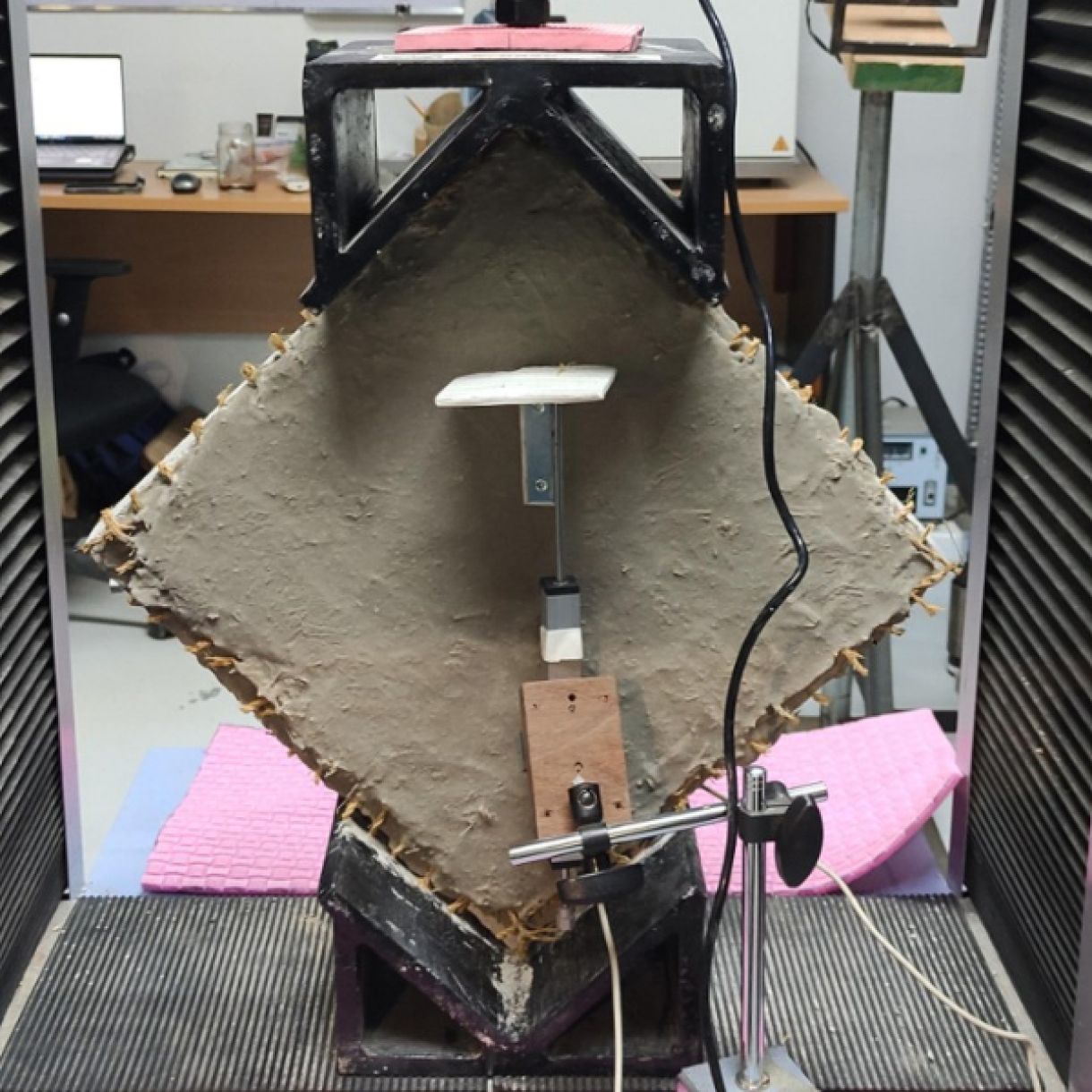

Buildings constructed using this innovative technology have demonstrated longevity and durability. Bamboo possesses impressive structural properties, including strength and flexibility. Structures built with CBFT can withstand various environmental conditions such as typhoons and earthquakes, reducing the need for frequent repairs or replacements. This extended lifespan contributes to resource conservation and the reduction of construction waste, supporting the circular economy’s goal of prolonging the useful life of products and materials.

Carbon Sequestration

Bamboo used in Cement-Bamboo Frame homes actively contributes to carbon sequestration. Bamboo plants absorb carbon dioxide from the atmosphere as they grow, acting as a carbon sink. By incorporating bamboo into the construction process, CBFT helps offset carbon emissions, by storing these into the Bamboo, thus mitigating the impacts of climate change. This carbon sequestration aspect aligns with the circular economy’s aim of regenerating nature and reducing greenhouse gas emissions.

Local Value Chain

Lastly, CBFT promotes local value chain development, creating employment opportunities and supporting local communities. BASE, through its comprehensive approach, ensures the active involvement of various stakeholders in the entire value chain, including bamboo farmers, treatment workers, and the local community. This localized approach not only drives economic growth but also facilitates knowledge transfer and skills development.

Indeed, CBFT contributes to the establishment of an inclusive and sustainable circular economy, where resources are maximized, waste is minimized, and communities thrive. Learn more about how we can build a sustainable future with Base.

Base Bahay Foundation, Inc (BASE) is the pioneer of Cement-Bamboo Framework in the Philippines. BASE builds affordable and disaster-resilient structures using bamboo-based technology. Through continuous research in the Base Innovation Center (BIC), BASE is optimizing the technology and looking for new applications outside its standard model. BASE also offers training courses under its Bamboo Academy program to share the alternative building technologies and provide further knowledge on bamboo construction. Learn more about BASE projects and initiatives!